When it comes to protecting your home from the elements, choosing the right roofing material is crucial. Rubber roofing systems have gained popularity in recent years due to their exceptional durability, performance, and longevity. In this comprehensive guide, we’ll delve into the world of rubber roofing systems, exploring their benefits, installation process, maintenance requirements, and more.

Understanding Rubber Roofing Systems

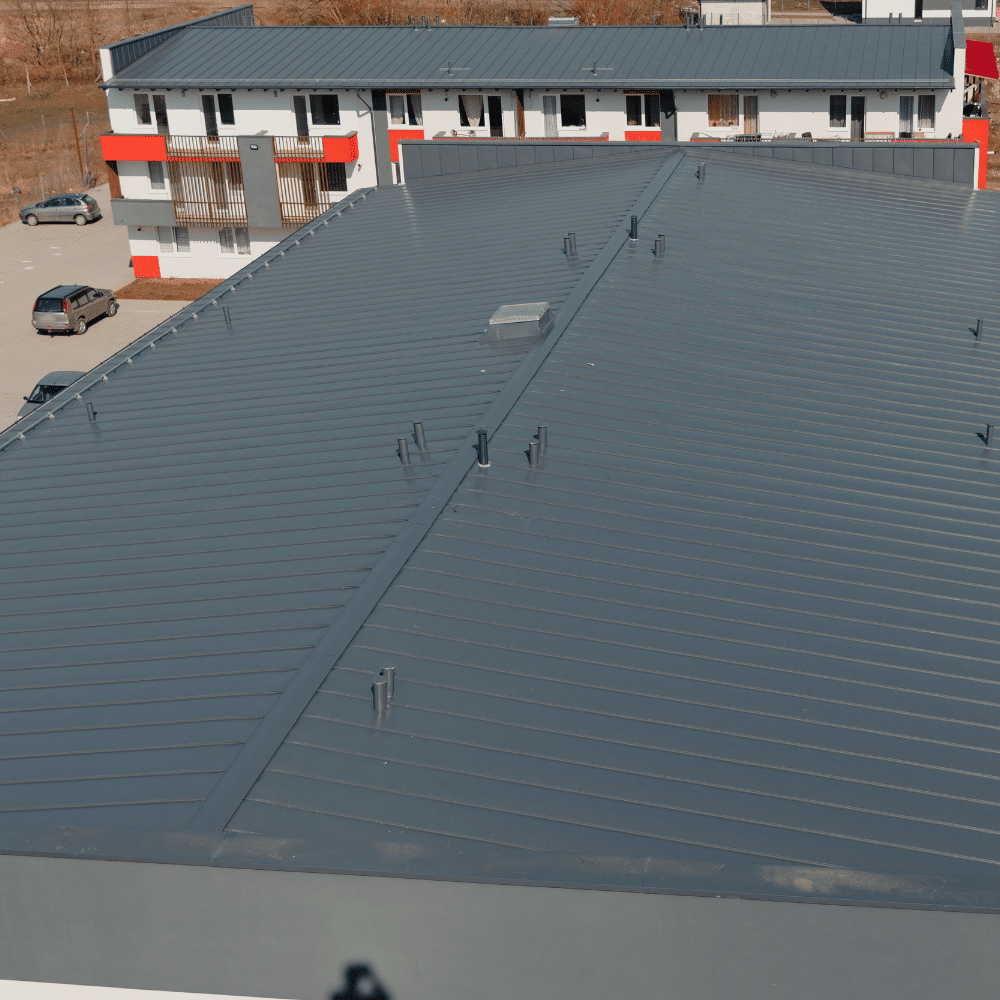

Rubber roofing, also known as ethylene propylene diene monomer (EPDM) roofing, is a synthetic rubber membrane commonly used for low-slope and flat roofs. Made from a blend of recycled materials, EPDM roofing offers several advantages over traditional roofing materials:

Durability

Rubber roofing systems are highly durable and resistant to weathering, UV radiation, ozone exposure, and extreme temperatures. With proper maintenance, EPDM roofs can last upwards of 50 years, making them a long-term investment in your home’s protection.

Waterproofing

EPDM membranes provide excellent waterproofing properties, effectively sealing out moisture and preventing leaks. The seamless installation of rubber roofing minimizes the risk of water infiltration, protecting your home from water damage and mold growth.

Energy Efficiency

Rubber roofing systems have inherent insulating properties that help regulate indoor temperatures and reduce energy consumption. By reflecting sunlight and minimizing heat absorption, EPDM roofs can lower cooling costs during the summer months, enhancing energy efficiency and comfort.

Installation Process

The installation of a rubber roofing system involves several key steps:

Surface Preparation

The roof substrate is cleaned and inspected for any damage or irregularities. Repairs are made as necessary to ensure a smooth and stable surface for the EPDM membrane.

Membrane Installation

EPDM membranes are available in large rolls, which are unrolled and laid out on the roof surface. The membrane is then trimmed to size and adhered to the substrate using a specialized adhesive or mechanical fasteners.

Seam Sealing

The seams and edges of the EPDM membrane are sealed using adhesive or tape to create a watertight barrier. Proper seam sealing is critical for preventing leaks and ensuring the longevity of the roofing system.

Flashing Installation: Flashing components, such as drip edges and termination bars, are installed to reinforce vulnerable areas of the roof and provide additional protection against water intrusion.

Maintenance and Care

While rubber roofing systems are relatively low-maintenance, routine care is essential to maximize their lifespan and performance:

Regular Inspections

Conduct visual inspections of your EPDM roof at least twice a year to check for signs of damage, such as tears, punctures, or loose seams. Promptly address any issues to prevent water infiltration and prolong the life of your roof.

Cleaning

Periodically clean your rubber roof surface to remove debris, dirt, and algae growth. Use a mild detergent and a soft-bristle brush to avoid damaging the membrane.

Avoid Harsh Chemicals

Avoid using harsh cleaning chemicals or abrasive materials on your EPDM roof, as they can damage the membrane and compromise its integrity.

Trust Recon Roofing for Your Rubber Roofing Needs

At Recon Roofing, we specialize in the installation, repair, and maintenance of rubber roofing systems for residential properties. Our experienced team is dedicated to delivering high-quality workmanship, exceptional service, and lasting solutions to protect your home for years to come.

Contact Recon Roofing Today

Ready to enhance your home’s durability and performance with a rubber roofing system? Contact Recon Roofing today to schedule a consultation with our knowledgeable team. Let us help you choose the perfect roofing solution to safeguard your home and enjoy peace of mind for years to come.